- Date added 19. 11. 2024

The 4th Industrial Revolution interconnects the worlds of advanced information technology and the manufacturing industry. It brings technological as well as social changes in the industry - according to estimates, productivity will increase by up to 30% and up to 40% of people will have to change their qualification. Are we ready for this? Who will need current workbench?

Imagine that every computer, mobile phone, but also a reader, camera, sensor, transmitter or lighting fixture are interconnected and communicate with each other. Thanks to this IoT (internet of things) connection, the devices can control production to some extent themselves. Artificial intelligence and self-learning algorithms for eliminating system errors and optimizing processes are already beginning to drive products to perfection.

We must not forget, among other things, the 3D scanning of the designed prototype and its conversion into a real 3D model, which leads to drawing-free production and interconnection of the entire production process.

Thanks to these technologies, the whole production process will not only become more efficient and faster, but especially will shift human work from manual, and still routine, to creative one.

A global survey related to Industry 4.0 with the participation of more than 1,600 managers from 19 countries, ten different industries and companies with an average revenue of $ 7.4 billion, as conducted by Forbes Insights in partnership with Deloitte Global last August, showed that the trend of smart manufacturing is much better utilised by beginners, resp. SMEs than current market leaders. They understand the need to invest in technology, but at the same time it can be difficult for them to seize new opportunities.

Bosch as global giant certainly is not idle in the new generation. It has already introduced several products and solutions for Industry 4.0, including Bosch TraQ, which aims to monitor (using sensors that send data) the shipped product on-line and send data o vibration, humidity, temperature or shock to a user who can take real-time countermeasures.

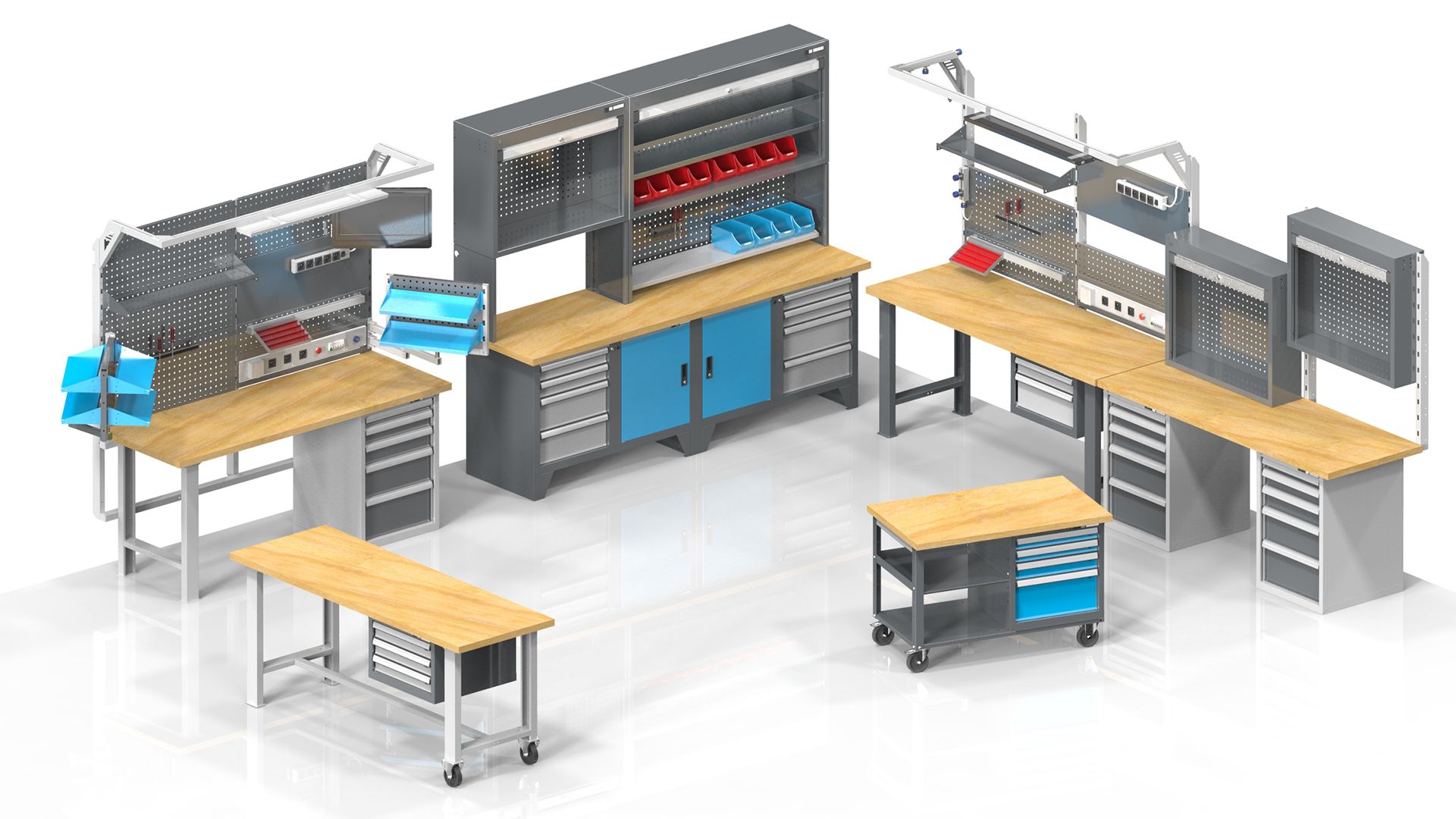

Within Industry 4.0, the current workbench will also have to undergo a transformation so as to be used in the future as well. Production automation and robotic workplaces are technologies that we know well and we are constantly modernizing. The development of the workshop furniture that we produce forms an integral part and a team of people is constantly dedicated to it. A lot has changed since the first VARIANT workbench was launched and we believe that we will not get lost in the new generation either. At the moment, it is not entirely clear, how, in what form and in which useful properties the current workshop furniture shall be transformed. All we can say for sure is that the changes have already begun.

Â

By sending the form, you express your consent with the storage of personal data in accordance with the provisions of § 5, paragraph 2 of Act No. 101/2000 Coll., On the protection of personal data, as amended. You agree that your personal data provided by you hereby will be processed and kept in an electronic database, only for the purposes of tenders and for a maximum period of 1 year. The consent may be revoked at any time in writing or electronically.

I agree